What Is a Self-Stacking Spiral Freezer Belts?

Unlike traditional conveyor belts, self-stacking spiral belts are uniquely designed to support their own weight in a helical structure. This allows the belt to stack vertically without external supports, enabling a compact footprint and efficient use of vertical freezer space.

These belts move products along a spiral path, ensuring uniform freezing while maintaining a continuous flow. The design eliminates the need for belt flipping or external guides, improving system reliability and reducing maintenance.

Self-Stacking Spiral Freezer Belts Key Features and Benefits

Energy-Efficient Design

Reduced Belt Tension: The spiral stacking mechanism lowers belt tension, decreasing wear and improving overall system lifespan.

Smaller Motor Requirements: Less tension means smaller motors can be used, reducing energy consumption and lowering utility costs.

No Belt Flipping or Overstretching

The stable structure prevents issues like belt flipping or stretching, offering smoother operation and reducing downtime.

Increased Product Throughput

Self-stacking belts allow for maximized product intake with consistent spacing, enabling faster freezing cycles and higher production volumes.

Compact Footprint

By optimizing vertical and horizontal space, these belts enable more efficient freezer layouts, which is ideal for facilities with limited floor space.

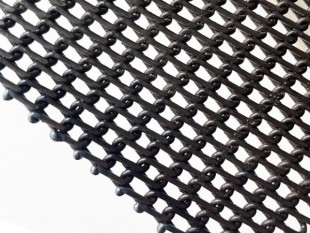

Enhanced Freezing Efficiency

The open belt design ensures optimal airflow and uniform freezing across all product surfaces, preserving food quality and texture.

Low Maintenance & Easy Sanitation

With fewer moving parts and a hygienic design, self-stacking spiral belts reduce the need for frequent cleaning and maintenance — saving time and operational costs.

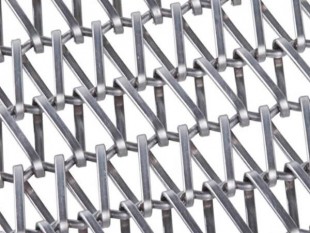

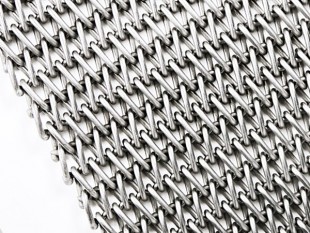

Self-Stacking Spiral Freezer Belts Technical Construction

One-sided Weave with Right-Hand Wind: Ensures structural integrity.

Interlocking Spirals: Features both round and oval pigtails that interconnect and attach to connecting rods for added stability.

Tension Links: Strategically placed to reinforce the belt edges.

Custom Mesh Configurations: Available to match existing or OEM systems without requiring structural modifications.

Belts can be directly spliced into existing systems, making partial replacements easy and cost-effective.

Self-Stacking Spiral Freezer Belts Material Options

Our self-stacking spiral belts are manufactured using high-quality stainless steel materials, including:

SS304 (AISI 304 Stainless Steel)

SS316 (AISI 316 Stainless Steel)

These materials are widely recognized in the food processing industry for their corrosion resistance, strength, and sanitary properties, making them ideal for demanding freezing environments.

Self-Stacking Spiral Freezer Belts Applications in Food Freezing

Self-stacking spiral belts are ideal for a wide range of frozen food processing lines, including:

Vegetables & Fruits: Lock in color, taste, and nutrients.

Meat & Poultry: Freeze cuts, nuggets, and processed meat products quickly.

Seafood: Maintain texture and flavor in shrimp, fillets, and more.

Bakery Products: Freeze dough, cakes, and pastries without drying out.

Ice Cream & Dairy: Smooth texture preservation and efficient hardening.

Ready-to-Eat Foods: Pizza, meals, and snacks benefit from rapid freezing.

+86-15369679157

+86-15369679157